Injection Molding Plastic Products for Business

Introduction

Welcome to Deepmould.net, your ultimate destination for high-quality injection molding plastic products. In this article, we will explore the advantages, applications, and benefits that injection molding brings to businesses in the metal fabricators industry. By leveraging the power of technology and expertise, our company aims to provide you with top-notch solutions tailored to your specific requirements.

What is Injection Molding and How Does It Work?

Injection molding is a highly efficient and versatile manufacturing process used to produce intricate and precise plastic products. It involves injecting molten plastic material into a specially-designed mold, allowing it to cool and solidify into the desired shape. This technique allows for mass production of plastic components with consistent quality and excellent reproducibility.

The Advantages of Injection Molding Plastic Products

1. Precision and Versatility: Injection molding enables the production of highly detailed and complex plastic parts, achieving tight tolerances that other manufacturing methods may struggle to match. This versatility allows businesses to create a wide range of products in various shapes, sizes, and complexities.

2. Fast and Efficient: With advanced machinery and automation, injection molding offers rapid production cycles, reducing lead times and increasing overall efficiency. This speed and efficiency make it an ideal choice for businesses seeking high-volume manufacturing.

3. Cost-Effective: Injection molding allows for the efficient use of materials, reducing waste and minimizing costs. Additionally, the ability to produce large quantities in a single production run helps drive economies of scale and lower the per-unit cost.

4. Superior Quality: With precise control over the manufacturing process, injection molding produces consistently high-quality plastic products, meeting the strictest industry standards. The use of advanced molds and machinery ensures exceptional surface finishes, structural integrity, and durability.

Applications of Injection Molding Plastic Products

The versatility of injection molding opens up a wide array of applications across various industries. Here are a few examples:

1. Automotive Industry

Injection molding plays a crucial role in the automotive sector. From interior components like dashboards, door panels, and buttons to exterior parts such as bumpers and headlights, the automotive industry heavily relies on injection molding to produce durable and visually appealing plastic parts.

2. Consumer Goods

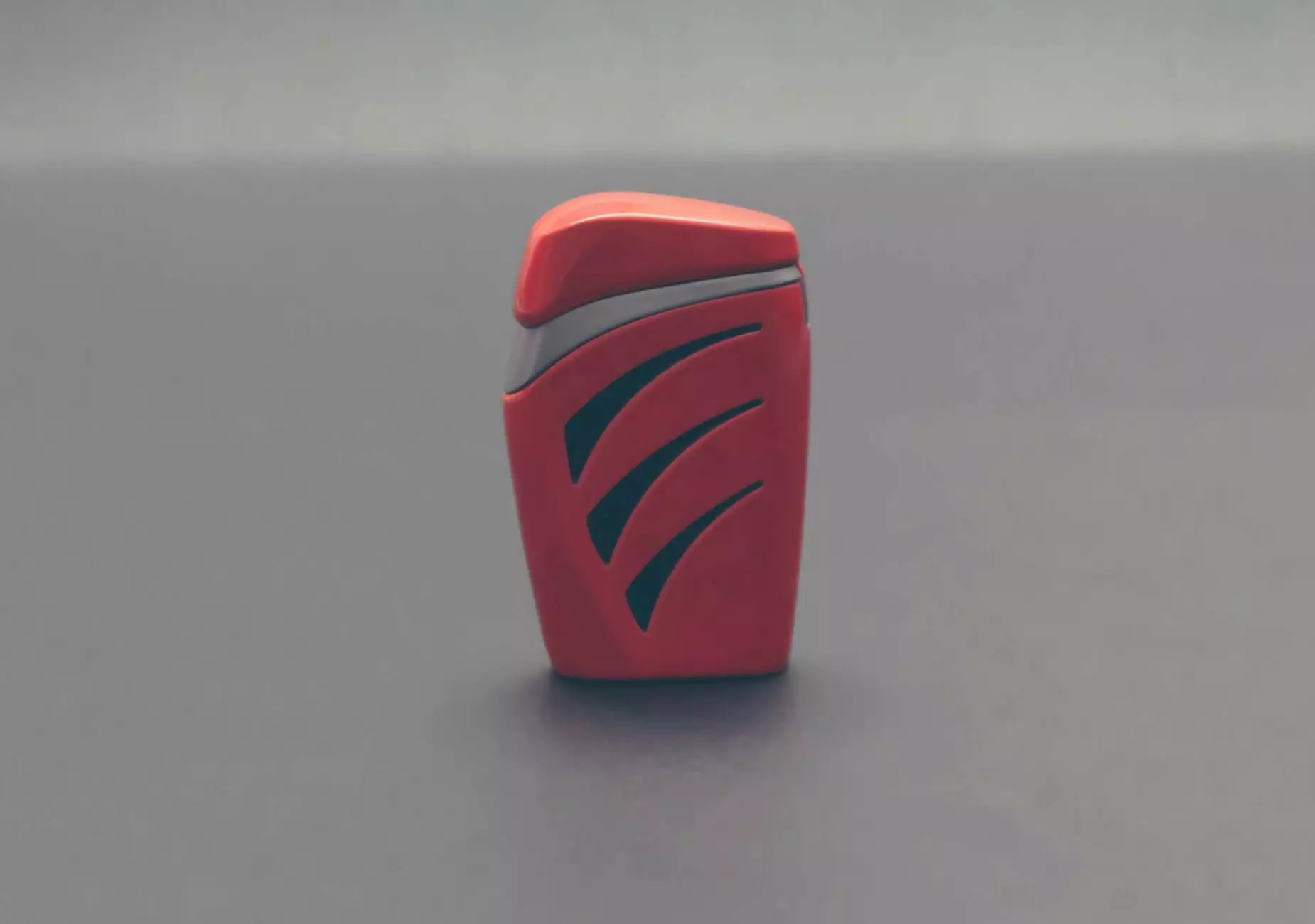

Injection molding enables the production of consumer goods like kitchenware, electronics, toys, and household items. The process ensures the creation of high-quality plastic products with excellent finishing, ergonomic designs, and precise functionality.

3. Medical Devices

The medical industry demands strict adherence to quality and precision, and injection molding meets these requirements. Medical devices such as syringes, inhalers, orthopedic implants, and diagnostic equipment benefit from the production capabilities and sterile manufacturing environment provided by injection molding.

4. Packaging

Injection molding is widely used in the packaging industry to create containers, bottles, caps, and closures. The process allows for efficient mass production while maintaining product integrity, ensuring a safe and reliable packaging solution.

Why Choose Deepmould.net for Injection Molding Plastic Products?

Deepmould.net specializes in providing top-quality injection molding plastic products for the metal fabricators industry. Here's why you should choose us:

1. Extensive Industry Experience

With years of experience in the field, we understand the unique challenges and requirements of the metal fabricators industry. Our expertise allows us to provide tailored solutions that meet the highest standards of quality and precision.

2. Technologically Advanced Facilities

At Deepmould.net, we have invested in state-of-the-art machinery and equipment to ensure efficient and accurate production processes. Our commitment to technological advancements allows us to deliver superior plastic products for your business.

3. Skilled and Dedicated Team

Our team consists of highly skilled professionals who are passionate about delivering excellence. From design and engineering to manufacturing and quality control, we are committed to providing you with customized solutions and exceptional service throughout the process.

4. Focus on Customer Satisfaction

Customer satisfaction is our top priority. We value your feedback and strive to exceed your expectations at every stage of the project. Our customer-centric approach ensures that you receive the best injection molding plastic products that precisely cater to your needs.

Conclusion

In summary, injection molding plastic products offer numerous advantages for businesses in the metal fabricators industry. From precision and versatility to cost-effectiveness and superior quality, injection molding is a reliable manufacturing process that meets the demands of various applications.

When it comes to injection molding plastic products, Deepmould.net emerges as the top choice for metal fabricators seeking exceptional solutions. With our extensive industry experience, advanced facilities, skilled team, and focus on customer satisfaction, we are dedicated to providing you with the best possible outcomes for your business needs.